Integrity Challenge

EMDs logging offers a cost-effective solution to determine the integrity status of the pipes without the requirement to pull the completion string. However, the logging interval is severely limited by the pump setting depth, beyond which no logging can be conducted. This leaves a significant part of the well unlogged and the condition of the pipe unknown. There are situations where the target depth for the corrosion logging cannot be achieved due to the pump setting depth. In these situations, the well will be moved from a planned standalone activity to a Hoist intervention. When the well activity is moved from a purely logging program to a workover intervention often a pressure test of the casing is viewed as sufficient confirmation of the well integrity. However, to conduct the pressure test a packer will be required to be set to test the casing. It may require several re-sets to get a good test due to corroded pipe. If the EMDs corrosion log had been run initially it would have provided the client with a detailed picture of the well integrity and the data could be used to identify a safe depth at which the packer could be set. This would enable the client to optimize subsequent operations, improving efficiency and resulting in time and cost savings.

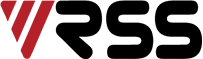

Corrosion Logging Result

One example when corrosion logging was done under Hoist operations is shown below:

The well is a horizontal oil producer drilled in 1995. After drilling the well was completed with a 13 3/8” conductor, 9 5/8” surface casing and a 7” intermediate liner. 4.5” wire wrapped screens (WWS) were installed across horizontal the open hole section from 1034 -1599 m. A 4.5” beam pump (BP) completion string was run.

In October 2008 the well was worked over and a 7” scab liner was run from surface to the top of the 7” intermediate liner. No pressure test on the 9 5/8” casing was done.

In 2023 a Hoist attended the well to replace the failed pump. The completion string was pulled and a scraper was run in hole to clean out the internal wall of the 7” scab liner and original liner before the pressure test. The scraper held up at a depth of 1000 m due to a wellbore restriction. After several attempts the scraper was pulled to surface. Attempts to mill out the obstruction also failed. A decision was taken to pressure test the 7” scab liner and liner with a retrievable bridge plug (RBP) set above the obstruction. The RBP was run in hole to 900 m. The Hoist was unable to conduct a pressure test because several attempts to set the packer at different depths in the interval of 800-900 m failed. An EMDs logging tool was run in hole to a target depth of 800 m to avoid getting the tool stuck.

The EMDs data indicated the presence of severe metal loss in the 13 3/8” conductor. There was an extended interval of severe corrosion in the 9 5/8” casing below the bottom of the conductor. Maximum metal loss was almost 50%. In addition, an extended interval of severe corrosion was detected in the 7” liner from the bottom of the logging interval at 805 m to the 7” liner hanger at 675 m. Maximum metal loss was identified at the bottom of the logging interval which was almost 100%. Furthermore, the EMDs tool captured severe metal loss in the lower part of the 7” scab liner with maximum metal loss of 70%. It appeared that corrosion from the liner had migrated upwards to the scab liner. Taking into consideration the EMDs data, there is high possibility that the scraper run hold up and unsuccessful milling occurred due to a collapse in the highly corroded 7” liner.

The example above shows that real time corrosion logging during critical operations such as a workover can provide integrity data of the well. This allows the workover program to be adjusted and eliminate unnecessary attempts to set a packer and will result in reduced Hoist operational time and ultimately saving significant costs.

All case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us