Integrity Challenge

Drilling through a loss zone leads to a high probability of poor cement quality and free pipe. If there is a corrosive aquifer, the possibility of external corrosion is increased drastically. It is critical to understand the integrity of the pipe across these areas. Regular logging is recommended to identify when corrosion will migrate from the outer to the inner pipes. This will enable a remedial program such as installing a scab liner to be planned before a catastrophic failure.

Corrosion Logging Result

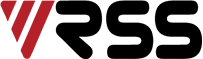

One example when corrosion logging was done in a 4 barrier well (strings) and metal loss on the outer casing was detected is shown below:

The well is a vertical open hole naturally flowing oil producer which was drilled in 1976. The well was completed with an 18 5/8” conductor, a 13 3/8” surface casing, a 9 5/8” intermediate casing with differential valve packer (DVP) for stage cementation and a tapered 7” intermediate liner. A 2 7/8” completion string was run.

In 1992 during a Hoist intervention the completion string was pulled and the 9 5/8” casing was successfully pressure tested. A 2 7/8” completion string was run. In 2001 a subsurface integrity test (SIT) was conducted and the B annulus leak-off test (LOT) failed. In 2005 a 7” scab liner was run from surface to the 7” intermediate liner hanger as a proactive measure. In 2009 a SIT was repeated and indicated that the B annulus (between 7” scab and the 9 5/8” casing) was good, however the C annulus (between 9 5/8” casing and 13 3/8” casing) LOT failed.

In 2019 EMDs corrosion logging was conducted to evaluate the integrity status of all pipes. The corrosion logging data indicated the presence of an extended interval of severe corrosion in the 13 3/8” casing just below the 18 5/8” conductor shoe. The maximum metal loss was 90%. In all probability the severe corrosion is the main root cause of the LOT failure. It was recommended to include this well in a corrosion monitoring program to track the possible migration of corrosion to inner pipe and estimate the annual corrosion rate.

All case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us