Challenge

How to accurately measure the injection distribution profile behind the pipe. Some injection wells have been designed to inject via the tubing and the A annulus simultaneously. Conventional PLT tools can only directly measure the flow splits in the tubing and not behind the pipe. For example, when perforated zones are covered by a tailpipe or behind tubing it is not possible to identify the fluid intake profile into those zones. Using the acoustic logging tool provides the Client with an accurate view of the injection profile behind the pipe.

Acoustic Logging Result

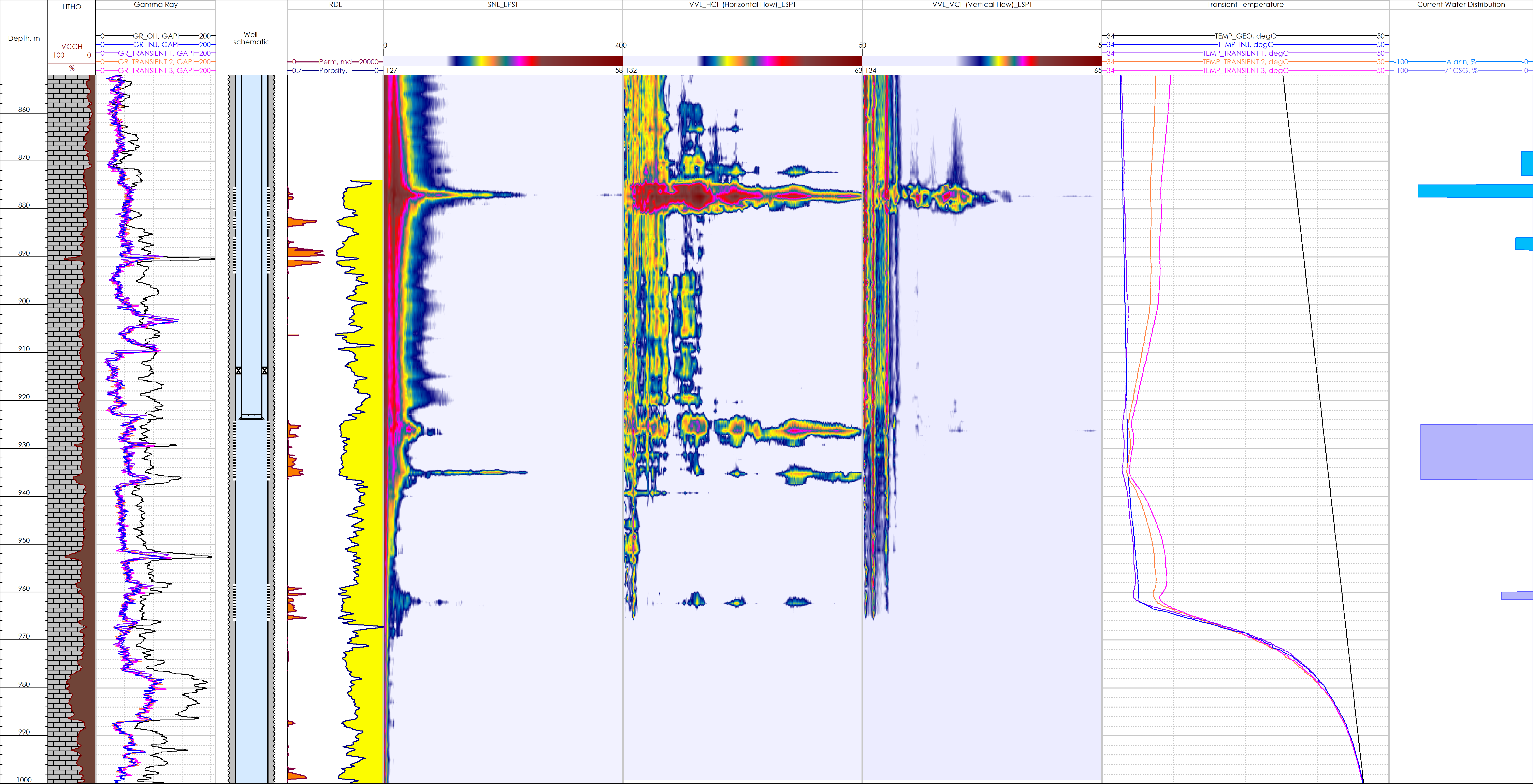

One example when acoustic logging was conducted in an injector well with dual injection (A annulus and tubing) is shown below:

The well is a vertical water injector drilled in 2010. The well was completed with a 9 5/8” surface casing and a 7” production casing. The 7” casing has 5 sets of perforations. The 4.5” tubing with a packer was run in hole. The packer was set to isolate 3 upper perforated intervals from 2 lower perforated intervals to allow selective injection: 2 lower intervals though the tubing, 3 upper intervals through the A annulus. The average injection rate in the A annulus is 45 m3/d and in the tubing 200 m3/d.

The PLT spinner cannot measure the injection profile behind the tubing and an acoustic log was run to identify the intake zones. The injection temperature curve combined with the vertical component of the VVL log data confirmed there was no injection beyond 962 m. The SNL log and the horizontal component of the VVL log indicated that there was only one intake zone across the 1st perforation interval which is taking all the injected water pumped into the A annulus, whereas the 2nd and 3rd intervals have no intake. The majority of the injected water which is pumped into the tubing is going into the upper part of the 4th perforated interval which is covered by tailpipe. Two additional intake zones were identified: One is at the bottom of the 4th perforated interval and second is at middle part of 5th perforated interval. Note, all the intake zones are very narrow so the sweeping efficiency is quite low.

Conclusion

Acoustic logging is a powerful technique to provide accurate reservoir flow behaviors behind pipe which would otherwise be missed if only using a conventional PLT string which cannot measure flow behind the casing. This can aid the Client to determine how to improve vertical sweep efficiency and thus improve the overall areal sweep efficiency for accurate 3D dynamic modelling.

All case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us