Tool Overview

The Pulsed Electromagnetic Tool is a non-destructive corrosion logging tool which was designed to measure the individual wall thickness of concentric pipes in a single run. The latest generation of this tool provides quantitative wall thickness measurement for up to 4-5 barriers.

Main Advantages

- Measures individual wall thickness of concentric pipes in a single run.

- No special well preparation requirement prior to logging e.g., scraper etc.

- Survey can be conducted in the presence of any type of fluid oil, water, gas.

- Presence or absence of cement behind pipes will not affect data quality.

- The unique design of sondes allows each coil to function as generating and receiving modes. This helps minimize tool length thus facilitating ease of operation in the field.

- The tool also incorporates Gamma ray, Temperature and Pressure sensors, therefore capturing additional information in a single run.

- The presence of multidirectional sondes can identify the type of defect, especially in the first barrier.

The advantages listed above make this tool the most cost-effective corrosion evaluation tool in the market.

The tool’s high resolution and sensitivity are achieved through a large dataset acquired from the electromagnetic sondes. Data processing done with proprietary software and metal loss calculation is based on the best match between real decay and calibrated decay. A huge calibration library is incorporated into the software and minimizes error in the metal loss calculation.

Integrity Benefits

In addition to the above listed advantages the EMDs tool can identify all completion and casing accessories in all pipes. For example, the tubing retrievable sub surface safety valve, sliding side door, wireline nipples, production packers and other completion components. Additionally, the log data can identify external components such as pipe centralizers.

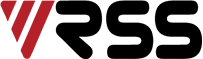

Well #1

The well is a vertical producer with no requirement for artificial lift and was drilled in 1998. The well was completed with a 13 3/8” surface casing, a 9 5/8” intermediate casing and a 5.5” monobore production string. The production string was run with a TSM tubing retrievable sub-surface safety valve (TRSSSV). The EMDs log data identified the TRSSSV and wraps of the hydraulic control line for the operation of the safety valve. The log data plots recorded by the short electromagnetic (E/M) sonde gives a greater vertical resolution due to its short length and clearly shows all the ID changes across safety valve assembly.

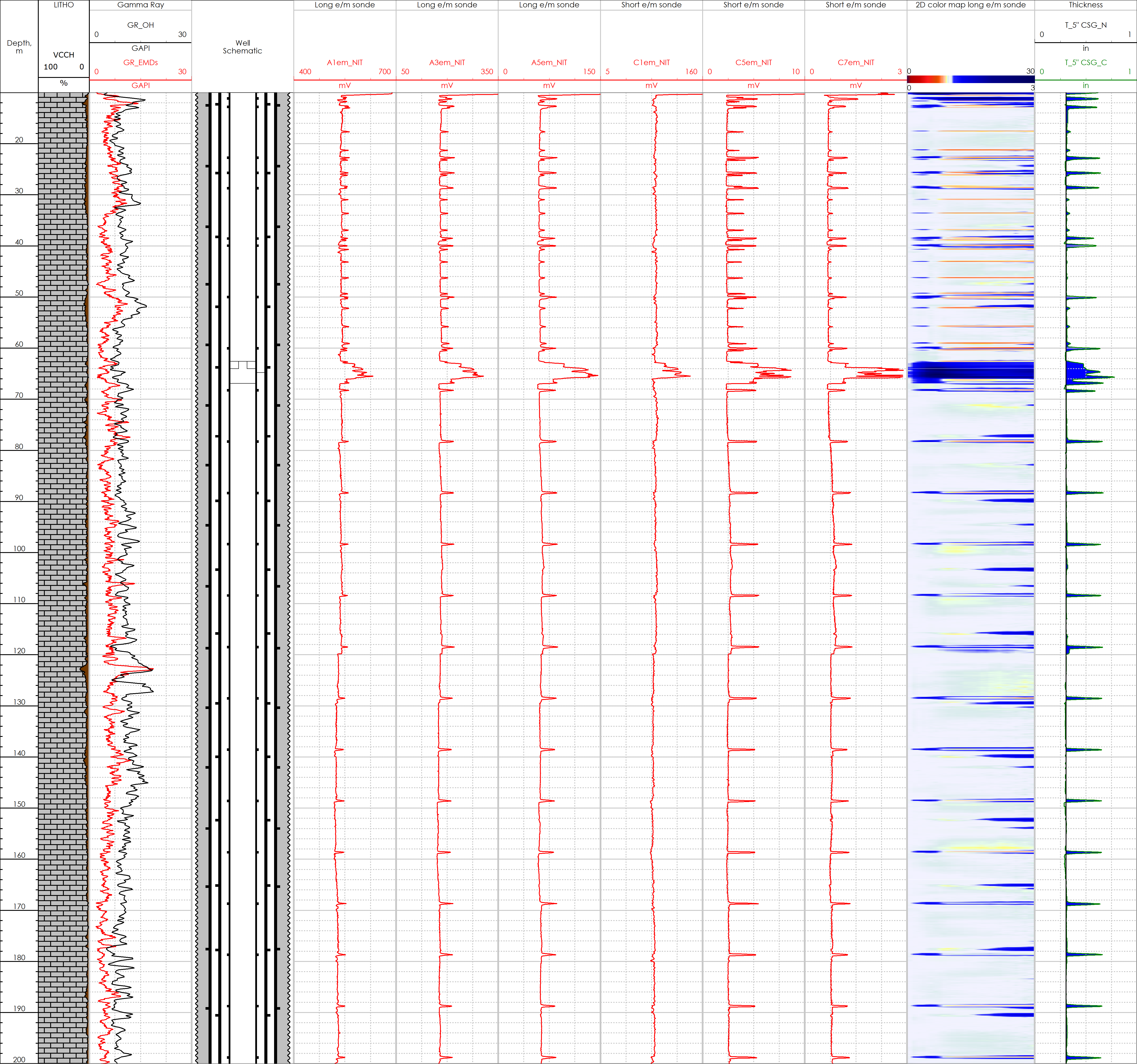

Well #2

The well is a vertical producer with no requirement for artificial lift and was drilled in 2013. The well was completed with a 13 3/8” surface casing, a 9 5/8” intermediate casing and a tapered 5.5” by 4.5” production string. The production string was run with an SP TRSSSV. The EMDs log data identified TRSSSV and the wraps of hydraulic control line for the operation of the safety valve. The log data plots show clearly all ID changes and the crossover from 5.5” to 4.5” at a depth of 102 m. The log data plots recorded by the short electromagnetic (E/M) sonde gives a greater vertical resolution due to its shorter length and clearly shows all ID changes across the safety valve assembly.

Conclusion

Taking into consideration the two wells above, it is clear that the data recorded by EMDs can identify all completion accessories in all pipes in the well, including external accessories such as clamps and centralizers.

The log data shows very clear ID changes across completion accessories. If the well history or completion diagram is unclear the log data can assist in identification and precise location of completion components.

Identification of all clamps on the outer surface of the pipe such as hydraulic control line clamps can be useful if the production string needs to be cut. The log data can also be used to identify an interval with no accessories such as casing centralizers to be selected thus minimizing complication during an intervention operation such as milling pipe for side tracking.

More case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us