Tool Overview

The Pulsed Electromagnetic Tool is a non-destructive corrosion logging tool which was designed to measure the individual wall thickness of concentric pipes in a single run. The latest generation of this tool provides quantitative wall thickness measurement for up to 4 barriers.

Main Advantages

- Measures individual wall thickness of concentric pipes in a single run.

- No special well preparation requirement prior to logging e.g., scraper etc.

- Survey can be conducted in the presence of any type of fluid oil, water, gas.

- Presence or absence of cement behind pipes will not affect data quality.

- The unique design of sondes allows each coil to function as generating and receiving modes. This helps minimize tool length thus facilitating ease of operation in the field.

- The tool also incorporates Gamma ray, Temperature and Pressure sensors, therefore capturing additional information in a single run.

- The presence of multidirectional sondes can identify the type of defect, especially in the first barrier.

The advantages listed above make this tool the most cost-effective corrosion evaluation tool in the market.

The tool’s high resolution and sensitivity are achieved through a large dataset acquired from the electromagnetic sondes. Data processing done with proprietary software and metal loss calculation is based on the best match between real decay and calibrated decay. A huge calibration library is incorporated into the software and minimizes error in the metal loss calculation.

Integrity Challenge

Drilling across a loss zone leads to a high probability of poor cement quality and free pipe. If there is a corrosive aquifer, the possibility of external corrosion is increased drastically. It is critical to understand the integrity of the pipe across these areas. Regular logging is recommended to identify when corrosion will migrate from the outer pipe to the inner pipe. This will enable a remedial program such as installing a scab liner to be instigated before a catastrophic failure.

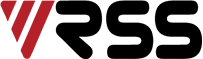

Corrosion Logging Result

One example when corrosion logging was done in a 4 barrier well (strings) and metal loss on the outer casing was detected is shown below:

The well is a vertical water injector drilled more than 40 years ago. After drilling the well was completed with 13 3/8” surface casing to 813 m, the 9 5/8” intermediate casing with the shoe at 1407 m and the 7” liner from 1252-1511 m. A 4.5” completion string was run in hole to 1400 m. In 2016 a Hoist was mobilized to location and the completion string was pulled. The 9 5/8” casing was successfully pressure tested and a 7” scab liner was run in hole from surface to the top of production liner. A 4.5” completion string was run in hole to 1435 m. In 2019 a subsurface integrity test (SIT) was conducted and the C annulus failed the leak off test (LOT).

In 2022 EMDs corrosion logging was conducted. Data from the logging revealed severe metal loss in the 13 3/8” surface casing at a shallow section of the well. This is probably the main cause of the C annulus LOT failure. From the data the Operator could then re-evaluate their C annulus management program e.g., reduce the maximum allowable surface annulus pressure (MAASP), increase annulus pressure monitoring and increase blow-down frequency if required. This may also result in a requirement to conduct more frequent corrosion logging to establish metal loss increase over time.

More case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us